Description

Details:

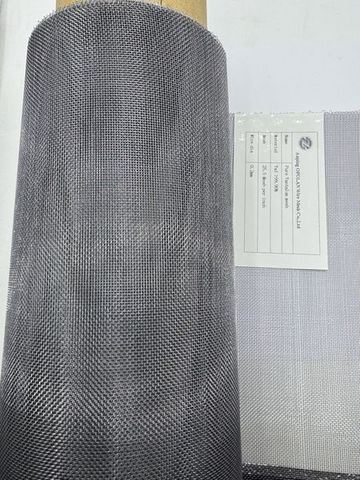

Product name:Refractory tantalum mesh, tantalum wire mesh, high-temperature niobium wire mesh, nuclear fuel niobium mesh

Grade:Ta1 Ta2

Mesh from : 8-300 mesh

Size : 50mm x 50mm

Density:16.6 g/cm

Melting point:2996 ℃

Characteristics of refractory tantalum mesh:

Tantalum mesh has good mechanical properties, stable chemical properties, and a large dielectric constant of the surface oxide film, making it a key modern functional material. The corrosion resistance of tantalum mesh is the same as that of glass. At medium temperature (about 150 ℃), only fluorine, hydrofluoric acid, sulfur trioxide (including fuming sulfuric acid), strong alkali, and some molten salts have an impact on tantalum mesh, and its corrosion resistance is better than that of titanium mesh and zirconium mesh.

The melting point of tantalum mesh is 2990 ℃, making it the third refractory metal after tungsten and rhenium. Although tantalum mesh has a high melting and boiling point, its electron escape work is lower than that of refractory metals such as tungsten mesh and molybdenum mesh. Due to its weak ability to emit electrons, it has been applied in electric vacuum technology.

Nuclear grade tantalum mesh application:

Tantalum mesh can withstand high temperatures, has good strength and stiffness, and is a high-quality material for making heating components, insulation components, and loading containers for vacuum high-temperature furnaces

Tantalum mesh and niobium mesh are used in the aerospace industry to make engine components for aerospace shuttles, rockets, submarines, etc., such as combustion chambers, combustion mesh ducts, turbopumps, etc.

Tantalum wire mesh and niobium wire mesh are high-quality aerospace materials used for rocket accelerator nozzles, spacecraft propulsion afterburner devices, nozzle valves, and more.

Tantalum mesh can be used to make capacitors and liners for armor piercing shells.

Tantalum mesh has a small neutron capture cross-section, high thermal conductivity and strength, and is used as a nuclear fuel cladding material, nuclear fuel alloy additive, and heat exchanger structural material in atomic reactors.

- wire mesh

- tantalum

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

Not informed

More about

Anping Ofolan Metal Wire Mesh Manufacture Co.,Ltd

10-50

Employees

100K - 200K

Sales volume (USD)

50%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- wire mesh

- titanium

- nickel

- tantalun

- stainless steel

Contact and location

-

Yue ********

-

+86 13********

-

HengShui / Hebei | China