Description

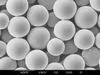

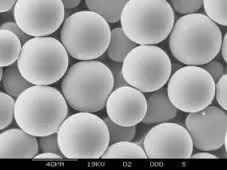

The process of burning coal in thermal power plants produces fly ash containing ceramic particles made largely of alumina and silica. They are produced at temperatures of 1,500 to 1,750 °C (2,730 to 3,180 °F) through complicated chemical and physical transformation. Their chemical composition and structure varies considerably depending on the composition of coal that generated them.<br />

<br />

Cenospheres or extendospheres are lightweight, inert, hollow, nonmetallic spherical materials, composed largely of silica (SiO2) and alumna (Al2O3). They have good flowability, ultra low density, nonpoisonous, corrosion-resisting, thermal stable, high partial strength, good insulating, sound isolating, low water absorption, low thermal conductivity that are extensively used in the rubber, equipment of glass fiber reinforced plastic, polyester, plastic as filler. Cenospheres also are utilized for coating, paint and oil industry. Cenospheres not only can reduce the weight of end products and cost but also increase the strength.

- Cenospheres

- extendospheres

- Perlite Microspheres

- Glass Bubbles

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

More information here http://bariteworld.com/industrial-minerals-products/cenospheres-extendospheres/

More about

BariteWorld

500-1000

Employees

2M - 10M

Sales volume (USD)

Not informed

Year

Established

Business type

- Industry / Manufacturer

- Distributor / Wholesaler

Keywords

- Calcium Carbonate

- Kaolin

- Dolomite

- Potassium Humate

- Silica Fume

- Silica Sand

- cenosperes

- barite

- Oil drilling chemicals

- Refractory materials

- Raw materials Ver Mais

Contact and location

-

Roman ********

-

+1 917********

-

Rockleigh / New Jersey | United States