Description

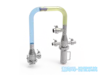

The primary purpose of a clean-up system is to remove or recover remnants left in the pipe after being transferred from one location to another in the production line

liquid. In its simplest form, the clean-up system consists of an elastic emission (also known as "small" ) slightly larger in diameter than the pipe in which the pipe needs to be cleared

pigs" or "cleaners") and then use water, other liquids, compressed air or gases, or even products being processed to drive the clean-up

The pipe passes through the pipe and removes or recycles the remaining product.

Increase product yield and reduce waste

In food and beverage pipes and other liquid handling pipes, materials are stored in almost all pipes as long as liquids are delivered. When I

Before we can run other products through the same production line, it is important to eliminate residual products. In most cases, we will

This is achieved through line process water or cleaning chemicals. However, this is time-consuming and uses a lot of resources. With this

At the same time, this process washes away fully available products.

HyPERFORE's product recycling system recycles almost the last remaining drop in the pipeline in fully controlled operation

products, thus increasing product yields and saving water and CIP chemicals. In addition, recycled products are not discarded as waste, but rather

Residual liquid is stored through a clean-up tube and pushed to its destination (cans, packaging, storage, anywhere).

Automated clean-up solutions further improve operations as labor costs increase and food safety regulations become more stringent, and we are looking for ways to reduce manual labor and increase automated use. Automation reduces errors, and more and more manufacturers use automation in many processes.

Hyperfore automated product recycling systems benefit manufacturers of food and beverage, pharmaceutical and food products because they are more efficient, reliable and safer than manual systems. Automatic recycling systems can also help manufacturers increase processing speed, minimize manual intervention and extend uptime.

- Clearing system

- pig head top material system

- product recovery system

- top liquid ball system

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

Not informed

More about

Beijing Hyperfore Technology Co.,Ltd.

10-50

Employees

100K - 200K

Sales volume (USD)

30%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Importer / Trading Company

- Business Service

Keywords

- pigging system

- pigging solution

- pig cleaning system

- product recovery system

Contact and location

-

Esther ********

-

+86 10********

-

北京 / 北京 | China