Description

Slag is a common problem in boiler operation in thermal power plant, the formation of slag seriously threatens the safe operation of boiler, shortens the service life of boiler equipment, causes the temperature of overheated steam to rise, leads to overheated steam temperature, and even leads to the blasting of soda pipe, reduces boiler efficiency, and there are safety hazards. In order to solve the above problems and effectively observe the situation of slag in boilers, a intelligent identification system of thermal boiler slag is developed.

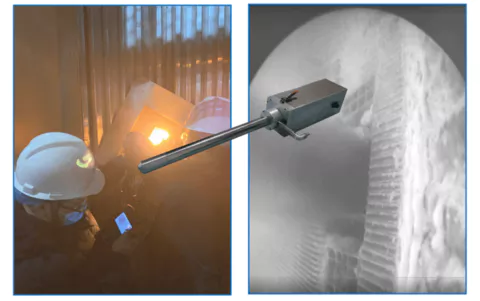

Based on spectral specialising optical imaging technology and pattern recognition technology, the system is applied to the real-time monitoring of boiler slag status, can view the slag, contamination and ash accumulation of each heated surface in the furnace, continuous monitoring and image analysis, determine the boiler pipe wear position and slag, contamination, ash location, and quantitative measurement. In order to take timely and effective measures to control the degree of slag, contamination, ash accumulation, to prevent the occurrence of passive shutdown of the furnace, while a greater degree of safety to ensure the safety of observers.

Features of the slag intelligent identification system:

1. Good on-site ease of use

Convenient use of compressed air for cooling (0.4 to 0.7MPa; 10 to 20 m3/h; 20 to 35 degrees C).

2. Flexible observation methods and a broad perspective

Movable or online observations;

With axial, radial dual viewing angle, with finely designed fine-branch detector can observe the thermal surface in the range of 5-10m near the fire hole;

Observation of the imaging temperature zone of 1600 to 150 degrees C, covering the boiler furnace to the hot end of the empty pre-generator.

3. High temperature resistance and long life

Equipment temperature resistance: 1600 degrees C (under wind cooling conditions);

Service life: can be used in the furnace for a long time;

Easy to maintain: localized, easy to maintain and repair

Benefits of the Slag Intelligent Identification System:

1. Optimize the ash blowing efficiency and reduce non-stop. Slag is the main problem affecting boiler efficiency and safety, slag will be irreversible, in serious cases, non-stop, and even accidents. In order to prevent slag, often by strengthening the frequency and pressure of blowing ash, excessive cleaning will lead to damage to the heat surface pipe, resulting in non-stop. Through the use of this equipment can find a reasonable mode of blowing ash, reduce the number of blowing ash.

2. Increase the proportion of poor quality coal mixed with burning. Because of the unknown slag situation, dare not rush to continue to improve the proportion of poor quality coal doping, the use of in-oven coking visualization technology can improve the proportion of doping, according to the increase of 5% of the calculation of the ratio of coal, the difference of 200 yuan per ton of coal, a 660MW thermal power unit annual (4500 hours calculation) coal consumption of about 1.35 million tons, saving 13.5 million yuan.

3. Reflect the people-oriented, reduce the personnel due to observation of slag fouling caused by the hidden dangers of safety accidents.

- Thermal boilers

- boiler slag

- boiler slag intelligent monitoring

Production Capacity:

118

Delivery Timeframe:

Within 45 Days

Incoterms:

Not informedPackaging Details:

Not informed

More about

Changzhou Rongbang Automation Equipment Co., Ltd.

50-100

Employees

1M - 2M

Sales volume (USD)

Not informed

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Boiler observatory

- coking observatory

Contact and location

-

James ********

-

+86 1********

-

常州 / 江苏 | China