Description

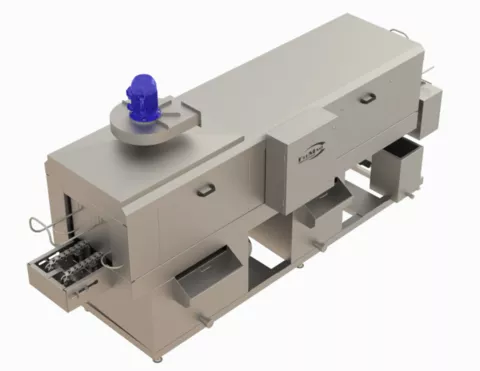

FT 1500 box washer

Double-chain dbelt box washer

Equipment with a capacity of up to 1500 boxes/hour, and may vary depending on dirt and process speed

Equipment dimensions:

O Height: 1900mm

O Width: 1300mm

The Length: 4900mm

Made of Stainless Steel AISI 304

Square tubular structure 80 x 80 mm

Conveyor of boxes/trays with independent motorization and speed configurable by frequency inverter

o PEAD polymer guides

o AISI 304 mass steel machined shafts

o Bearings with stainless steel bearing

o Splash collecting chute arranged on the mat headboards

o AISI 304 massive steel box driving guides

Basin and reservoirs made of 2.00 mm thick AISI 304 steel sheet

Protections and access doors in 1.59 mm AISI 304 steel plate with interlocked safety devices

Physical barrier type "chapel" installed at the entrance and exit of boxes made of folded profile of Steel Plate AISI 304 of 1.59 mm thickness

Finish in micro glass standby.

All welds through TIG process, standard sanitary welds.

1.1.2 - Internships

The washing process will take place in 04 stages, being:

o Pre-wash with hot water - 25 hp motor pump | 30 m3/h

o Washing with detergent - 15 hp motor pump |25 m3/h

o Rinse - 15 hp motorcycle pump| 25 m3/h

o Sanitizer - 07 m3/h motor pump

Steam exhaust system made through hood and rotor - it is at the customer's discretion to make pipe to direct the steam out of your factory

Direct steam water heating, containing pressure relief valve at the inlet of the equipment and manometer

Water heating by electrical resistance on request

Equipment has water reservoirs for recirculation - each reservoir is equipped with filtration system through metal screens for waste collection

Water intake in reservoirs controlled by electromechanical valve.

Drain for water outlet with electromechanical valve, and time can be programmed for water exchange by HMI

1.1.3 - Control panel

Full integrated electrical frame for equipment

Double protection cover

Siemens electrical components

Parameterization and monitoring of the process by operation HMI - the user can adjust the temperature, operating status, fault screen, manual or automatic mode, time drains, among others.

Access and maintenance doors secured with fasteners and safety sensor

Control and emergency buttons included

o On/off

o Emergency

the Reset

Complete control board - all components necessary for operation included

Component brands: SIEMENS and or SCHNEIDER, according to availability

1.1.4 - Exhaust system (optional)

Complete exhaust system for collection of steam from equipment and conduction for existing outlet pipe or outside the factory

Hood for steam collection to be installed on the equipment manufactured in a folded profile of 1.59 AISI 304 steel plate fixed to the ceiling

02 meters of steam driving pipe included

- box washer

- stainless steel

- refrigerator

Production Capacity:

Not informed

Delivery Timeframe:

Within 45 Days

Incoterms:

CIF - Cost, Insurance and Freight

EXW - Ex Works

Packaging Details:

Not informed

More about

Fitmaq Equipamentos LTDA

10-50

Employees

2M - 10M

Sales volume (USD)

Not informed

Year

Established

Business type

- Industry / Manufacturer

- Business Service

Keywords

- industrial equipment solutions

Contact and location

-

Vilmar ********

-

+55 49********

-

Chapecó / SC | Brazil