Description

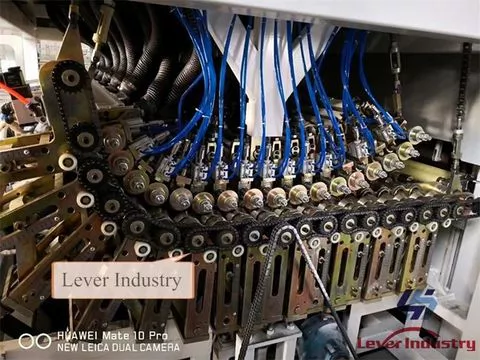

Lever TFB-SERIES BI-DIRECTION FLAT & BENDING GLASS TEMPERING FURNACE (RIGID SHAFT BENDING)

Video link:

https://youtu.be/0BF-2QNbcaI

Model Max. Bending Loading Area Min.Glass Size Thickness Min.Radius

(mm) (mm) (mm) (mm)

LV-TFB1206L 1200 x ⌒600 150 x 280 3~19 ≧350

LV-TFB1608L 1200 x ⌒800 150 x 280 4~19 ≧450

LV-TFB2010L 2010 x ⌒1000 150 x 280 4~19 ≧500

LV-TFB2412L 2440 x ⌒1200 150 x 280 4~19 ≧550

LV-TFB2415L 2440 x ⌒1500 150 x 320 5~19 ≧700

LV-TFB3025L 3000 x ⌒2500 150 x 320 5~19 ≧1200

Machine Main Features:

►. Heating section has a helix matrix structure, which can control the temperature of each area independently. Reasonable design and unique structure of heating elements make a long serve life.

►. The heating oven body is full closed and the Insulating materials are of high quality material with top performance which can ensure very lower energy consumption.

►. Fault diagnosis system for the heating elements.

►. We use only two connecting communication between the thermocouples and computer, which will avoid the interruption and make the temperature-measuring more exact.

►. The working condition of every thermocouple could be monitored automatically, and the warning will come out if there is any abnormal situation.

►. Adopting PID for temperature control, which has the better anti-interference function and higher temperature-control precision.

►. Equal three phase power consumption during automatic heating up period; avoiding phase no-equal during no-heating period automatically.

►. The fine-adjustment for oven temperature could be achieved by fine-adjusting the temperature of every heating element.

►. During the night, the furnace can stay at sleep mode around 500-550 degrees centigrade and preheating takes place before the start of the shift in the morning so that the furnace is ready for production

►. The production process, temperature, time, air pressure, etc could be recorded. Therefore, testing production could be saved and production stability could be improved. Also, the production state in different batches could be tracked.

- glass tempering furnace

- safety glass machine

- tempered glass

- glass toughening plant

Production Capacity:

15

Delivery Timeframe:

Within 90 Days

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

EXW - Ex Works

FOB - Free on Board

Packaging Details:

seaworthy

More about

Glass Furnace

50-100

Employees

2M - 10M

Sales volume (USD)

Not informed

Year

Established

Business type

Keywords

- glass tempering furnace

- glass tempering machine

- glass tempered furnace

- glass lamination machine

- windshield glass machine for automotive

Contact and location

-

Kevin ********

-

+86 37********

-

Luoyang / Henan | China