Description

Main features: <br />

1. Through adjustment of operating frequency, the jig frequency of pumping units can be changed. 2. The rotate speed of motor can be changed through adjusting operating frequency.<br />

3. Up and down stroke speed of pumping units can be changed through adjusting frequency and time separately.<br />

4. Energy feeds back to power grid, so the saved energy can be 16%-24% more than that from using energy consumption braking resistor.<br />

5. Reactive power can be reduced through improving power factor, so as to reducing line loss.<br />

<br />

Specification<br />

YSCJS series of frequency-conversion energy-saving synergy control system for pumping units is designed according to the working characteristics of pumping units in oil field, with signal acquisition and disposal functions, taking advantage of frequency conversion and speed regulation technologies, which is a high-efficiency, energy-saving automatic control system reducing largely the production cost of crude oil. It can start from zero speed or in soft start manner saving energy, which helps motor drive the system to the rated rotate speed in a stable manner limiting the start current, without defects, such as impact on power grid or rapid power consumption due to over-current upon starting. Up and down stroke can be adjusted at will according to the characteristics of oil wells during operation, to reduce electricity consumption as well as increase oil production. In addition, half of a pumping unit is generating power during the operation of up and down stroke because the pumping unit is operated with variable loads. Generally, the generated power by a braking resistor used for a frequency converter of a general motor will be wasted. However, our company develop a frequency-conversion speed-regulating multi-functional control device used for pumping unit by ourselves, which can feed back such generated power during a certain time to the power grid for recycling, through such links as following up, regulating pressure and power feedback and recycling. This action reduces energy loss of power supply network, takes full advantage of energy, and improves the power factor from the former approximately 0.3 to now above 0.96, saving energy obviously. Technical parameters:<br />

1. working voltage: three-phase AC 380V±10% or 1140V±10%, 50Hz<br />

2. Altitude: < 1,000 m<br />

3. Ambient temperature: -30 - + 50℃ <br />

4. Motor power: 15 - 315 kW<br />

5. Voltage/frequency characteristics: high performance torque vector control<br />

6. Frequency Regulation: 0 - 50Hz<br />

7. Braking mode: energy feedback/braking unit<br />

8. Speed regulation ratio for jig frequency: 2.5<br />

9. Failure detection: lack of phase, overload, locked-rotor<br />

10. Protection level: IP44<br />

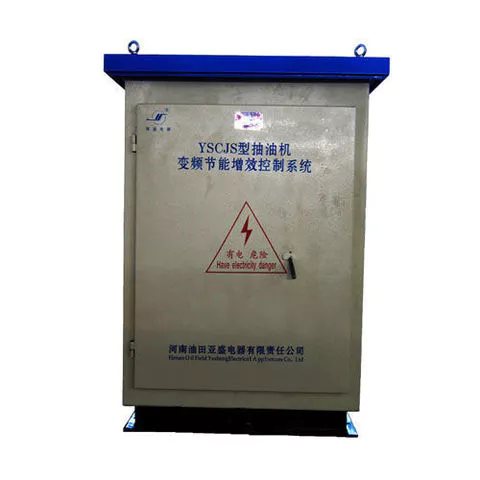

- Frequency-conversion energy-saving control cabinet for pumping units

Production Capacity:

200/day

Delivery Timeframe:

Depends on Size of Order

Incoterms:

Not informedPackaging Details:

Packed in boxes

More about

Henan Oilfield Yasheng Electrical Appliance Co., Ltd.

50-100

Employees

500K - 1M

Sales volume (USD)

10%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Distributor / Wholesaler

Keywords

- Protector

- motor protector

Contact and location

-

Xiaorui ********

-

+86 37********

-

Nanyang City / Henan Province | China