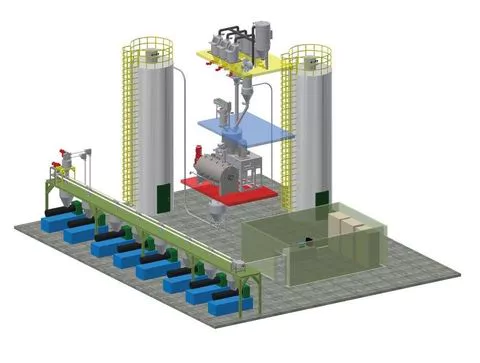

Description

The manufacturing of PVC products is a compounding process to convert PVC resins and other compositions required as per formulations to the semi-final products or final products.

The process flow diagram of a general rigid PVC product manufacturing is as follows:

The manufacturing process starts from the handling of raw materials.

De-bagging of Raw Materials

The 2 major materials PVC resin and calcium carbonate are usually packed in 25kg bag or ton bag, or tank truck if large scale production. Other solid additives are usually packed in 25kg bag.

Dumping Station

Solid powder PVC resins and other materials are de-bagged and dumped into the stainless steel bin or silo.

Silos

- Automatic PVC metering mixed conveying system

Production Capacity:

10

Delivery Timeframe:

Within 90 Days

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

FOB - Free on Board

Packaging Details:

nacked, wooden box, plastic film

More about

Kenneth Mechanical Engineering Technology(Suzhou) Co., Ltd

50-100

Employees

1M - 2M

Sales volume (USD)

40%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Importer / Trading Company

Keywords

- PVC Mixers

- PVC Compounding Machinery

- PVC Pelletizing Machine

- PVC Blenders

Contact and location

-

Mark ********

-

+86 1********

-

Zhangjiagang / Jiangsu | China