Description

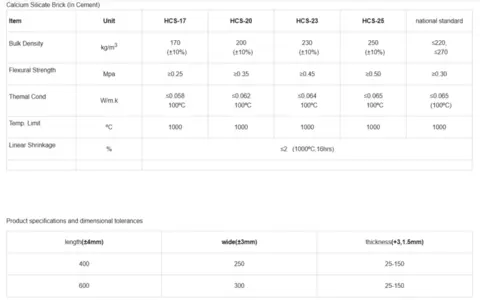

Here is an introduction to it: • Main components: Typically made from quartz and lime as the main raw materials, synthesized through dynamic hydrothermal processes into the main crystalline phase of hard calcium silicate, with added reinforcing fibers. It does not contain asbestos or other harmful substances. • Performance characteristics: It features high heat resistance, with a maximum heat resistance temperature of up to 1050℃. Simultaneously, it has low thermal conductivity, strong insulation performance, low density, low heat storage, high specific strength, good durability, and corrosion resistance. It can be cut and sawed, making construction convenient. • Product classification: Based on different densities and temperature resistance ranges, it can be divided into ordinary calcium silicate boards (temperature resistance ≤600℃), high-density calcium silicate boards (temperature resistance ≤1000℃), and ultra-high temperature calcium silicate boards (temperature resistance ≤1100℃). • Technical Specifications: Its bulk density is between 200-1200 kg/m³, flexural strength ≥ 0.35 MPa, compressive strength ≥ 0.65 MPa, thermal conductivity ≤ 0.050 + 0.00011 tW/m·K, maximum operating temperature is 1000℃, and linear shrinkage ≤ 2% (1000℃, 16hrs). • Application Areas: Widely used in cement, non-ferrous metallurgy, metallurgy, petrochemical, power, glass, ceramics and other industries. It can be used for energy-saving and heat preservation projects of industrial kilns, such as rotary kilns and decomposition kilns in the cement industry, and heating furnaces and ethylene cracking furnaces in the petrochemical industry. • Installation and Construction: It can be bonded using high-temperature bonding powder and water glass to prepare adhesive, or it can be fixed with ordinary building fasteners. During construction, the bonding surface must be cleaned, and the bonding thickness should be controlled at 1.5-2 mm.

- High temperature resistance up to 1000 degrees Celsius

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

Not informed

More about

Laizhou Mingfa Thermal Insulation Material Co., Ltd

50-100

Employees

2M - 10M

Sales volume (USD)

30%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- calcium silicate boards

Contact and location

-

Dylan ********

-

+86 53********

-

烟台市 / 山东省 | China