Description

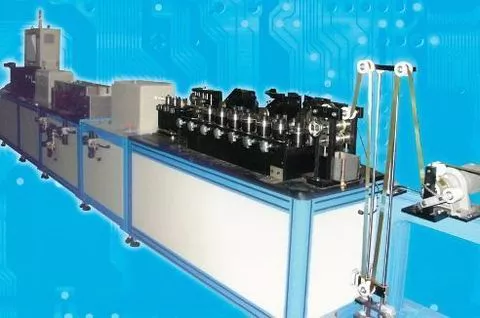

LOCKSEAM SINGLE TINNING TUBE MACHINE<br />

*Uncoiler<br />

* Forming rollers<br />

*Flux device<br />

*Tinning device<br />

*Cooling device<br />

*Straight roller<br />

*Cutting device<br />

*Tube stacker<br />

*Control cabinet<br />

*Strip : brass<br />

*Machine Dimension :L8900 * W1420 * H1800 mm<br />

A. GENERAL REQUIREMENTS<br />

<br />

1. MACHINE CAPABILITY<br />

*MAX.CUTTING SPEED: MAX 60- 70M / MIN<br />

<br />

*CUTTING SPEED DEPENDING ON CUTTING<br />

LENGTH<br />

Length 200mmàspeed 20M/min(100cuts/min),<br />

500mmàspeed 50M/min (100cuts/min)<br />

700mmàspeed 65-68M/min(100cuts/min)<br />

1000mmàspeed65-68M/min(70cuts/min)<br />

<br />

*REMOTE CONTROL FOR SET UP OPERATIONS<br />

<br />

*TUBE LENGTH : 200-2,000MM PROGRAMMABLE<br />

ONTO TOUCH PANEL<br />

<br />

*CUTTING LENGTH AND QUANTITY (TO BE<br />

PRODUCED) WILL BE PROGRAMMED INTO<br />

TOUCH PANEL UPTO 5 LENGTHS. <br />

<br />

*TINNING DEVICE: TUBE WILL BE NO LEAKING <br />

AS THE LOCK SEAM OF TUBE WILL BE COVER<br />

/COATED BY TIN<br />

<br />

2. UTILITIES <br />

*ELECTRICITY: ACCORDING CUSTOMER<br />

REQUEST<br />

*COMPRESSED AIR: 6 BAR<br />

Technical Description for Single Tinning Tube Mill<br />

1. Strip Section<br />

a. Coil stand (with braking system): range of O.D. 200 <br />

(TBD)-800mm(max.), max 150kg <br />

b. Uncoiler system: motor, 1/2HP 1/6, 380VAC 50HZ<br />

0.4KW<br />

c. Strip tension device: 2 potentiometers to control <br />

strip tension<br />

<br />

2. Forming Section<br />

a.Forming and sizing rolls<br />

This is composed of 7 sets of forming and sizing rolls<br />

which quenching heat treatment and precise grinding. <br />

b.Mandrel: with Nitride heat treatment<br />

c. Driving Motor:<br />

3HP 1/6, 2.25KW, 380VAC 50HZ<br />

d. Fluxing Unit:<br />

Material: plastic P.P., anti- acid, volume 20 l<br />

Pump: anti-acid, 110VAC, 60HZ, 0.1KW<br />

e. Control panel:<br />

There are three kinds of inverter 5HP ,3HP &1HP <br />

inside<br />

<br />

3. Tinning Unit:<br />

a. Main Frame:<br />

Material: steel enveloped by 1.5mmt of 316 stainless<br />

steel sheet<br />

b. Tinning Pump:<br />

1HP, 6P, 50HZ, 0.75KW <br />

c. Tinning Tank:<br />

Material: whole SUS316, 4mmt<br />

d. Heater:<br />

Material: SUS316, 3 pcs x 4 KW=12 KW<br />

e. Cooling Tank:<br />

Material: plastic, volume 130 l<br />

<br />

4. Calibrating (straightening) section<br />

a. Calibrating (straightening) rolls<br />

Same as the forming & sizing rolls<br />

Straightness : +/-0,5mm/ 1Meter<br />

b. Measuring Roll:<br />

Rotary encoder<br />

c. Cutting system:<br />

Servo motor: MITSUBISH<br />

<br />

5.Main feature of cutting system <br />

cutting knife of cutting system is wear-resistance and

long working life<br />

b.cutting tolerance accurate +/-0.3mm<br />

c.no burrs of cutting side<br />

d.cutting side is not deformed<br />

<br />

<br />

6. Tube stacker:<br />

Material: steel frame enveloped with SUS 304 / fair <br />

surface <br />

<br />

<br />

<br />

<br />

- tinning tube machine for copper radiators

Production Capacity:

Not informed

Delivery Timeframe:

Within 90 Days

Incoterms:

FOB - Free on Board

Packaging Details:

wooden case

More about

radiators machines/radiators/oil coolers/beverage machines/parts

10-50

Employees

2M - 10M

Sales volume (USD)

Not informed

Year

Established

Business type

- Industry / Manufacturer

- Importer / Trading Company

- Representative / Agent

Keywords

- radiator machines

- radiators

- oil coolers

- brakes

- maching parts

- milling parts Ver Mais

Contact and location

-

May ********

-

+886 6********

-

Tainan / | Taiwan