Description

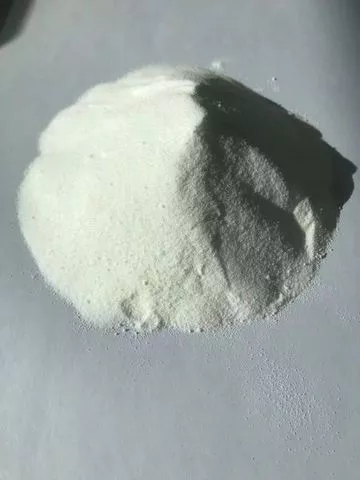

Oxidized polyethylene wax is an excellent new type of polar wax, because the molecular chain of oxidized polyethylene wax has a certain amount of carbonyl and hydroxyl groups, so the compatibility with fillers, pigments, and polar resins has been significantly improved. The wettability and dispersibility in the polar system are better than those of polyethylene wax, and it also has coupling, and its performance is comparable to that of Honeywell A-C wax in the United States.

OPE wax has special properties such as low viscosity, high softening point, good hardness, no toxicity, good thermal stability, low volatility at high temperature, excellent dispersion of fillers and pigments, excellent external lubricity, strong internal lubrication, and coupling effect, which can improve the production efficiency of plastic processing, reduce production costs, and have good compatibility with polyolefin resins, good moisture resistance at room temperature, strong chemical resistance, excellent electrical properties, can improve the appearance of finished products, is to replace Montan wax, Sichuan wax, Ideal for liquid paraffin, microcrystalline paraffin, natural paraffin, polyethylene wax, etc.

It is used as a dispersant, lubricant, brightener and coupling agent for pigments or fillers such as concentrated masterbatch, polypropylene masterbatch, additive masterbatch, filler masterbatch, etc. As a rubber and plastic processing lubricant, release agent and phase solvent, EVA wax has good compatibility with various rubbers, due to its high melting point and low viscosity, promote good fluidity of resin, relatively reduce the power consumption of resin mixing, reduce the adhesion of resin and mold, easy to decoat, play the role of internal and external lubrication, and has good anti-static properties. As a dispersant of ink, anti-anti- Oxidized polyethylene wax is used as a viscosity modifier for hot melts.

- Oxidized wax

- high density

- Honeywell

- BASF

Production Capacity:

15000

Delivery Timeframe:

Immediate

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

FOB - Free on Board

Packaging Details:

25 kg bag and 40 bags per pallet

More about

shandong Repolyfine chemical co.,ltd

10-50

Employees

500K - 1M

Sales volume (USD)

90%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- pvc additives manufacturer in China

Contact and location

-

Barret Wang

-

+86 533 xxxxxxxx

-

zibo / | China