Description

Low operating energy consumption: No high-pressure pump is required to power the membrane; it primarily relies on suction pumps or gravity discharge. The energy consumption of aeration and scrubbing is significantly lower than the high-pressure transport energy consumption of external ultrafiltration systems, resulting in overall operating costs that are 30%–50% lower than traditional processes. Suitable scenarios: Large-scale wastewater treatment plants and reclaimed water projects, meeting cost reduction needs. Strong anti-fouling capability: Combined with a bottom aeration system, the turbulence generated by rising bubbles continuously washes the membrane surface, effectively reducing the adsorption and deposition of pollutants such as sludge and suspended solids, extending the membrane module cleaning cycle, and reducing the frequency of chemical cleaning and reagent consumption. Small footprint and flexible installation: The membrane module is directly immersed in the water tank, eliminating the need for complex piping and high-pressure equipment. High system integration: For the same treatment scale, the footprint is only 60%–70% of that of external ultrafiltration systems. Modular design allows for flexible installation in expansion or retrofit projects. The effluent boasts stable and high-quality water quality, effectively removing suspended solids, colloids, bacteria, viruses, and other impurities. Turbidity remains consistently below 0.1 NTU, and SDI (Soil Degradation Index) is <3, making it suitable as a pretreatment source for reverse osmosis (RO), particularly ideal for the upstream processes of seawater desalination and pure water production. Operation and maintenance are simple and highly automated, enabling remote monitoring and start-up/shutdown. Membrane module disassembly and replacement require no downtime, minimizing maintenance workload. It exhibits strong adaptability to fluctuations in influent water quality, maintaining stable operation even with short-term increases in influent turbidity. Significant cost advantages (suitable for export business): As an alternative to similar products from Mitsubishi and Asahi Kasei, domestically produced submerged ultrafiltration membranes offer cost advantages in raw materials and production processes, while performance parameters match international standards, resulting in outstanding cost-effectiveness.

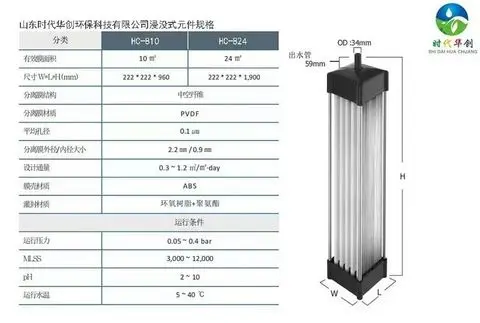

- Ultrafiltration membrane

Production Capacity:

10000

Delivery Timeframe:

Within 45 Days

Incoterms:

FOB - Free on Board

Packaging Details:

Not informed

More about

SHANDONG SHIDAI HUACHUANG ENVIROMENTAL CO.,LTD.

10-50

Employees

100K - 200K

Sales volume (USD)

70%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- MBR membranes

- ultrafiltration/nanofiltration membranes

- flat sheet membranes

- reverse osmosis membranes

Contact and location

-

Amy ********

-

+86 8********

-

YANTAI / SHANDONG | China