Description

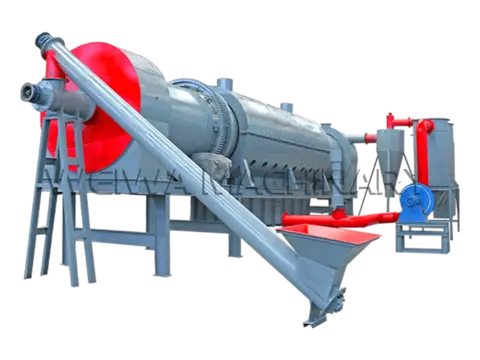

Continuous Carbonization FurnaceWhat is a continuous carbonization furnace? A continuous carbonization furnace is a new type of environmentally friendly carbonization equipment. After passing through the carbonization furnace, the biomass material is converted into charcoal and can be further processed. Compared with other carbonization equipment, this carbonization furnace for coal flakes can be used continuously for 24 hours to reach high output, so it is called a continuous carbonization furnace. The entire production process does not produce harmful gases, does not pollute the environment, and is excellent among various carbonization furnaces. Acceptable biomass for continuous carbonization furnacesContinuous carbonization furnaces are mainly used for various biomass materials: fruit shells, wood waste, sugarcane bagasse, crop stems, rice husks, coconut shells, peanut shells, peanut shells, sunflower seed shells, shells, palm kernel shells, walnut shells, almond shells and pistachio shells, etc. At the same time, electronic waste, cans, waste lines, sludge, household garbage and other materials with biomass characteristics can also be used as raw materials for continuous carbonization furnaces (size less than 20mm, moisture less than 15%)How to use a continuous carbonization furnaceThe whole carbonization process mainly includes crushing, drying, Feeding, Carbonization, Discharging, Combustible Gas Recovery, Waste Gas Treatment, and Briquette Production. 01 Pre-treatment Crushing (optional): The crushing system processes the raw materials into target size (less than 20mm). Drying (optional): The drying system processes the raw materials into moisture content less than 15%. 02 Carbonization Feeding: The raw biomass (wood chips, sawdust, crushed coconut shells etc.) is automatically fed into the furnace by conveyor belt, screw feeder or Z belt. Carbonization: After heating the main furnace, the temperature rises gradually. The initial temperature helps to dry some moisture in the raw materials. When the temperature reaches 250 degrees Celsius, demethylation begins. Combustible gas begins to be produced. At 280 degrees Celsius, the exothermic reaction begins. The hydrocarbon molecules are separated into smaller carbon molecules and hydrogen. Charcoal begins to be produced. As the temperature hits 450 degrees Celsius, aromatic ring compounds begin to react. 3 Discharging Charcoal: Through three stages of water cooling discharger, Charcoal below 45 degrees Celsius is collected. Tar & Wood Vinegar Collection (Optional): Through the condenser, tar (biomass oil) and wood vinegar are separated and collected separately. Charcoal Briquette Making (Optional): After being processed by the charcoal briquette machine, the original shape of the charcoal can be turned into the desired shape, such as round, square, poke, etc. 04 Combustible Gas Recovery After condensation and sulfur removal treatment, the combustible gas can be recovered and reused. We can also introduce the excess heat of the carbonization furnace into the dryer to recover the combustible gas, thereby saving fuel for the dryer. 05 Exhaust Gas Treatment The exhaust gas is treated by the spray tower, water curtain tower, and cooling tower. The treated exhaust gas meets the EU emission standards. WEIWA Group provides high standard customized exhaust gas treatment systems. Features of Continuous Carbonization Furnace Equipped with Alarm Devices The PLC electric cabinet has an alarm device, and there will be an alarm display and alarms for some electrical faults. With explosion-proof water seal There is an explosion-proof water seal on the combustible pipe (in order to prevent abnormal pressure of combustible gas in the equipment). Frequency fan guides the direction of gas in all pipes led by fans (the fan is variable frequency), when the pipe is blocked, it will be displayed on the PLC. High thermal efficiency The material has no contact with flue gas and will not be polluted by hot air. Good energy-saving effect The thermal utilization rate of the equipment is high, and the use of air before the converter can effectively increase the thermal efficiency by 5-10%, and the energy-saving effect is very good. Learn more about the characteristics of biochar Biochar is a carbonaceous substance formed by the carbonization of biomass (such as wood, agricultural waste and other plant residues). The biochar production equipment ensures that the pyrolysis reaction is carried out under high temperature and oxygen-free conditions. This production method gives biochar the following characteristics: Porous structure: Biochar has abundant micropores on its surface and inside. The pore structure gives biochar a high specific surface area, which can reach 200-500m2/g. The structure gives biochar an effective adsorption capacity and helps to store water and nutrients. Rich functional groups: The surface of biochar usually carries a variety of functional groups (such as hydroxyl groups, carboxyl, ETC. ). These groups provide many active sites to form chemical bonds with minerals, microorganisms, organic matter, ETC. , thereby increasing its adsorption capacity. High Stability & Durability: The carbon in biochar exists mainly in aromatic and structured forms. Therefore, it has strong chemical and thermal stability and degrades very slowly in soil or environment. Generally speaking, biochar can even exist in soil for hundreds of years. Sustainable Application of Biochar from Continuous Carbonization Furnace The unique chemical properties of charcoal production from continuous carbonization furnaces bring about a wide range of applications and great economic value. Biochar charcoal is widely used in agriculture, medicine, civilians, and other industries. Application of Biochar in Carbon Removal Industry Carbon Removal Carbon Credit Trading: The quantified carbon reduction effect of biochar making machine generates carbon credits. Biochar producers can sell it on the carbon market to companies with excessive carbon emissions. Carbon Sequestration: The carbon content of biomass comes from the atmosphere2 absorbed by photosynthesis. Biochar carbonization equipment stably stores this carbon in biochar. This avoids carbon emissions from natural degradation of biomass. Application of Biochar in Sustainable Agriculture Sustainable Agriculture Reduces Agricultural Pollution: The use of fertilizers and pesticides causes agricultural pollution. Biochar as an alternative can ease dependence on them. Therefore, This reduces the negative environmental impact caused by agricultural activities. Restoration of soil fertility: The unique pore structure of biochar can absorb nutrients and release them slowly from the soil to reduce losses. In addition, biochar can optimize microbial activity and pH in the soil. They all create favorable conditions for crop root growth. Application of biochar in the forest industry Forestry forest fire prevention: There are a lot of accumulated woody waste in the forest. They are prone to cause large fires under drought or high temperature conditions. By converting woody waste into biochar, biochar equipment fundamentally reduces the risk of fire. Forest ecological restoration: In forest restoration projects, biochar can provide a stable carbon source to accelerate vegetation growth. This helps plants better adapt to harsh environments. This is closely related to the United Nations' SDG15 (Protect & Restore Terrestrial Ecosystems). Models and Types of Continuous Carbonization Furnaces for Sale Model Input Capacity Motor Power Weight Dimensions (m) L1 800-1200kg/h 22KW 8-9t 12.5*5.5*3 L2 1200-2000kg/h 28KW 9-10t 12.5*6.5*4.5 L3 2000-3200kg/h 28KW 12-14t 12.5*7.5*5.5 L4 3200-4800kg/h 32KW 14-16t 12.5*7.5*5.5 Packaging & Shipping 1,The machines will be loaded into the container by waterproof facric. 2,The big size equipment is waterproof packing,small parts will be packed into wooden box. 3,Special packing request as customer's demand. Start business here! So far, we have customers from more than 130 countries, Indonesia, India, Malaysia, Laos, Myanmar, Thailand,Vietnam,Philippines,Pakistan, Sri Lanka, Lebanon, Georgia, Turkey, Poland, Czech, Mongolia, South Korea, Romania, Egypt, Sudan,Tunisia,Algeria, Ethiopia, Tanzania Equatorial Guinea, Zambia, Mexico, South Africa, ETC.

- Continuous carbonization furnace

- carbonization furnace

- charcoal making machine

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

CIP - Carriage and Insurance Paid to

CPT - Carriage Paid to

DAF - Delivered At Frontier

DDP - Delivered Duty Paid

DDU - Delivered Duty Unpaid

DEQ - Delivered Ex Quay

DES - Delivered Ex Ship

EXW - Ex Works

FAS - Free Along Ship

FCA - Free Carrier

FOB - Free on Board

Packaging Details:

Not informed

More about

Weiwa machinery

100-200

Employees

Not informed

Not informed

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Carbonization furnace

- charcoal machine

- briquette machine

Contact and location

-

Henan ********

-

+86 1********

-

郑州市 / 河南省 | China