Description

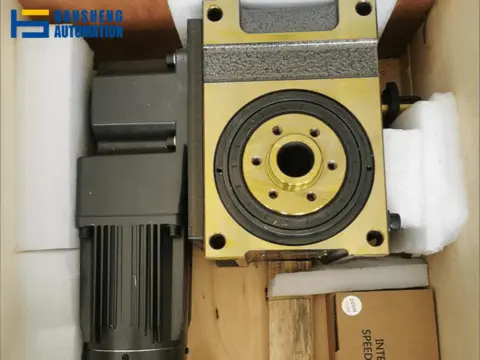

As one of the cam indexer product lines under Hansheng Automation, the Hollow Flange Cam Indexer differs most significantly from other product series by featuring a through-hole hollow structure for both the flange and the output shaft. This design allows for easy routing of cables, air tubes, hydraulic lines, and other conduits, effectively avoiding issues such as wiring difficulties and tangling in dense wiring scenarios. Below, we take the specific model 80DFH as an example for a detailed description.

Product Overview

Model 80DFH Hollow Flange Cam Indexer is a high-precision intermittent indexing component we offer. Serving as a core transmission component for automated equipment, its innovative integrated hollow structure enables internal wiring routing. Coupled with a indexing accuracy of ±30 arc seconds and excellent load-bearing capacity, it effectively addresses three major pain points in automated production lines: "inaccurate positioning, crowded space, and integration difficulties." It is widely compatible with industrial automation scenarios such as lithium battery production, precision assembly, intelligent packaging, and electronic and medical equipment manufacturing.

Product Advantages

Integrated Hollow Design: The flange and output shaft feature a through-hole hollow structure, allowing easy passage for cables, air tubes, hydraulic lines, and other conduits. This completely eliminates external line tangling issues, making it suitable for equipment requiring dense wiring, such as robotic arms and rotary worktables.

Ultra-High Indexing Accuracy: Boasts an indexing accuracy of ±30 arc seconds (equivalent to a positioning error per revolution of <0.01°). In scenarios like lithium battery electrode stacking or electronic component welding, this ensures workpiece alignment deviation ≤0.1mm, directly reducing product defect rates.

Strong Load-Bearing Performance: The output shaft can withstand radial loads of 330 kgf and axial loads of 420 kgf, stably driving workpieces up to 50 kg in continuous operation. It is suitable for small to medium-sized automated workstations. The input shaft can tolerate combined stresses of 350 kgf radial load and 260 kgf bending force.

Product Structure and Working Principle

Core Structure:

The device consists of a hollow flange, cam mechanism, input wheel, output shaft, bearings and support mechanism, lubrication system, housing, and positioning mechanism. The hollow flange provides a channel for routing conduits. The precisely machined cam accurately controls the output shaft movement by meshing with roller bearings. The bearings and support mechanism are made of high-strength metal to ensure operational stability under high-speed and heavy-load conditions. The built-in lubrication system reduces friction and wear between the cam and rollers. The housing protects the internal precision components and reduces operational noise. The positioning mechanism, combined with the cam geometry and roller mechanical limit, ensures the output shaft accurately stops at the indexing points.

Working Principle:

Driven by a motor, the input shaft rotates the cam. The specialized curved surface on the cam real-time regulates the position and motion trajectory of the rollers, thereby guiding the output shaft to perform periodic intermittent rotations according to preset angles. This ultimately achieves precise indexing and fixed-point stopping of the equipment, meeting the cycle time and accuracy requirements for multi-station operations in automated production lines.

Key Technical Parameters

Total weight: 32 kg

Moment of inertia of the input shaft during dwell phase: 9×10⁻³ kgf·m²

Indexing accuracy consistently maintained at ±30 arc seconds

Allowable torque for the output shaft: Please contact us for detailed drawings

The device is compatible with motors ≤2.2 kW, and the coaxiality deviation between the input shaft and the motor must be controlled within ≤0.1 mm.

Applicable Scenarios

Lithium Battery Industry: Applicable to equipment such as cell stacking machines, module assembly lines, and electrode slitting machines.

Packaging Machinery: Suitable for high-speed labeling machines, carton forming machines, and filling production lines.

Electronic and Medical Equipment Fields: Can be used in PCB inspection machines, syringe assembly machines, and infusion tube welding equipment.

- Hollow Flange Cam Indexer

- 80DFH Series Cam Indexer

- High-Precision

- Indexing Component

- Hollow Shaft Indexer

- Lithium Battery

- Production Line Indexer

- Automated High-Precision Indexing

- Integrated Wiring Indexer

- Heavy-Duty Cam Indexer

Production Capacity:

10000

Delivery Timeframe:

Within 30 Days

Incoterms:

Not informedPackaging Details:

Not informed

More about

Hansheng Automation (Dongguan) Co., Ltd.

10-50

Employees

1

Sales volume (USD)

90%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Cam Indexers

- Hollow Rotary Tables

- Planetary Gearboxes

- Harmonic Drives

- Gear Manufacturer

- Custom Gears

- ISO 5 Gear Manufacturing

- High-Precision CNC Machining

- Custom CNC Machining

- Precision Castings Ver Mais

Contact and location

-

Karim ********

-

+86 1********

-

东莞市 / 广东省 | China