Description

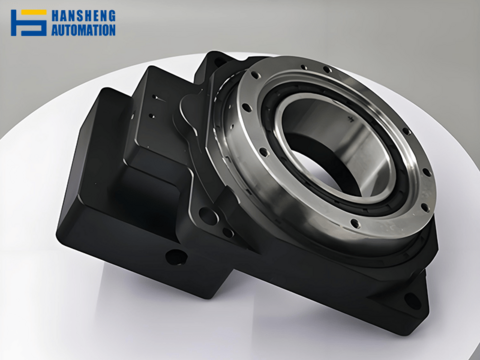

The Hansheng Automation Hollow Rotary Reducer is a high-precision rotational mechanism engineered as a direct replacement for DD motors and cam indexers in demanding automation applications. It masterfully combines exceptional operational efficiency, micron-level precision, robust rigidity, and outstanding cost-effectiveness. It is ideally suited for precision assembly lines, automated inspection systems, multi-station processing platforms, and similar high-accuracy scenarios.

Product Advantages

1.Ultra-Precise Transmission: Incorporates hardened helical gears (HRC60). Delivers standard repeat positioning accuracy of ≤15 arc seconds, with customizable options achieving ≤10 arc seconds.

2.Integrated Hollow Design: Features a central through-hole (15-120mm, customizable) for seamless routing of cables, pneumatic lines, or optical fibers. This integrated design simplifies wiring for end-effectors (e.g., grippers) and allows direct workpiece mounting, streamlining loading/unloading processes.

3.Broad Operational Adaptability: Offers a wide reduction ratio range (5-500), making it versatile for both high-speed, light-duty operations (e.g., 30-100 rpm for sorting) and low-speed, high-torque applications (e.g., 5-20 rpm for turning heavy workpieces). Load and speed adaptation is highly flexible.

4.High Compatibility: Designed for seamless integration with 100W to 1500W servo or stepper motors from major brands (e.g., Mitsubishi, Delta, Siemens) using standard flanges, enabling quick installation without custom adapters.

Key Performance Parameters

1.Positioning Accuracy: Standard ≤15 arc sec; Custom ≤10 arc sec

2.Central Through-Hole: 15-120mm (customizable)

3.Reduction Ratio: 5-500

4.Compatible Motors: 100W ~ 1500W Servo/Stepper

5.Speed Range: 30-100 rpm (high-speed), 5-20 rpm (high-torque)

6.Gear Hardness: HRC60 (Hardened)

Typical Applications

Precision assembly lines, automated inspection equipment, multi-station index tables, material handling & sorting systems, heavy workpiece positioning/ turning stations, optical component processing equipment.

Case Study: 6-Station Machining Cell

For an Indonesian client requiring a solution with a 40kg load capacity and a 600mm table diameter, we recommended the HRT200JS-L1-SV2 model. This configured a 6-station system (4 for machining, 2 for load/unload), achieving a fast 1-second index time with a 15-second dwell. The actuator's high stability and precision significantly boosted the client's production efficiency.

Service & Selection Support

1.Complimentary Sizing Service: Our engineers provide one-on-one support. To recommend the optimal model, please provide: Load weight, Table diameter, Maximum required speed, Application drawings/photos, Installation orientation (horizontal/vertical/suspended).

2.Customization Options: We support custom through-hole sizes, accuracy grades, mounting interfaces, and other modifications to meet specific application requirements.

3.Installation & Maintenance Guidance: We provide clear instructions for motor integration and mounting. Recommended maintenance includes regular lubrication, bearing checks, and temperature/vibration monitoring to ensure long service life.

Ready to Optimize Your Automation Design?

Contact Hansheng Automation today for a detailed product selection proposal or a custom quote. Leverage our technical expertise and high-value solutions to enhance your automated production systems.

- hollow rotary reducer

- precision rotary index table

- DD motor alternative

- 15 arcsec rotary actuator

- hollow shaft rotary stage

- automation rotary gearbox

- servo motor rotary reducer

Production Capacity:

10000

Delivery Timeframe:

Within 30 Days

Incoterms:

Not informedPackaging Details:

Not informed

More about

Hansheng Automation (Dongguan) Co., Ltd.

10-50

Employees

1

Sales volume (USD)

90%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Cam Indexers

- Hollow Rotary Tables

- Planetary Gearboxes

- Harmonic Drives

- Gear Manufacturer

- Custom Gears

- ISO 5 Gear Manufacturing

- High-Precision CNC Machining

- Custom CNC Machining

- Precision Castings Ver Mais

Contact and location

-

Karim ********

-

+86 1********

-

东莞市 / 广东省 | China