Description

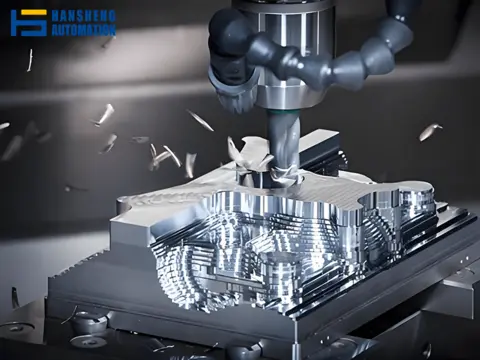

Hansheng Automation specializes in providing customized CNC machining solutions (including drawing evaluation, material/surface treatment recommendations). Its core business encompasses the manufacturing of tobacco packaging machines and core components for packaging machinery. It can process various materials such as metals and plastics, and is equipped with five-axis machining centers, turning-milling composite machine tools, and other equipment.

The company follows a seven-step process: "CAD Modeling → CAM Programming → Machine Setup → Machining Execution → Quality Inspection → Post-Processing → Product Testing." It provides full-chain services from drawing review to after-sales service (two-month warranty), particularly capable of meeting the stringent requirements for precision and hygiene in tobacco packaging machine components.

Advantages

High Precision: CNC machining precision reaches ±0.002mm (ultra-mirror finishing), ±0.005mm (precision grinding/milling).

Strong Multi-Axis Capability: Supports 3-5 axis simultaneous machining, capable of processing complex geometric structures like medical devices and helical surfaces.

Diverse Material Processing: Compatible with metals (aluminum, steel, iron, titanium alloys), engineering plastics (PEEK, ABS), and composite materials.

High Production Efficiency: Enables efficient continuous production, suitable for large-volume manufacturing scenarios.

Common Equipment

Kashifuji Gear Skiving Machine KPS30

Vertical Machining Center (maximum machining size 1200X840)

Horizontal Machining Center (maximum machining size 1200X840)

CNC Automatic Mold Making Equipment

Seibu Wire Electric Discharge Machine (WEDM) M50B

Taesin CNC Milling Machine TXC-T6.

CNC Machining Material Selection

Aluminum Alloys: 6061-T6, 7075-T6, 5052-H32

Stainless Steels: 304, 316L, 17-4PH

Titanium Alloys: Ti6Al4V, Ti-3Al-2.5V

Copper Alloys: H62 Brass, C110 Copper

Engineering Plastics: PEEK, PC, ABS

Quality Control System

Raw Material Inspection: Verification of metal composition using a spectrometer (e.g., nickel content in stainless steel, purity of aluminum alloys).

In-Process Inspection: 100% dimensional verification after the first article test cut, 10% sampling inspection during mass production.

Finished Product Inspection: Dimensional tolerances measured with a coordinate measuring machine (CMM), surface quality measured with a roughness tester, transmission precision of gears measured with a gear tester. A complete inspection report is provided.

FAQ

Can your company's CNC machining precision meet the stringent requirements for tobacco packaging machine parts?

Our CNC machining covers all precision levels: ultra-mirror machining precision is ±0.002 mm, precision grinding/turning precision is ±0.005 mm, and general turning precision is ±0.01 mm. This complies with the tight tolerance requirements for transmission components in tobacco packaging machines (such as cam indexers and gears). Furthermore, core transmission components (e.g., custom backlash ≤ 5 arc seconds for gear sets and P0 grade clearance ≤ 1 arc minute for planetary gearboxes) are calibrated using gear testing machines and three-coordinate measuring machines (CMMs).

What materials do you recommend for tobacco packaging machine parts?

Based on the requirements of "hygiene, corrosion resistance, and low wear" for tobacco packaging machines, we recommend the following materials: stainless steel (304/316L), aluminum alloy (6061-T6), and brass. We can provide material selection advice according to the specific working conditions of the parts and match them with appropriate processing techniques (such as anti-galling treatment for stainless steel and anodizing for aluminum alloy).

What information do I need to provide to customize CNC parts for tobacco packaging machines? How long does the entire process take?

We require 2D/3D drawings (e.g., CAD/SolidWorks format) indicating key dimensional tolerances, surface roughness, and working conditions (e.g., force and temperature).

The customization process involves three steps: (1) Drawing review + Material/Process confirmation; (2) Small-batch sampling/testing; (3) Mass production. The overall lead time can be shortened by negotiating urgent requirements.

- Precision CNC Machining

- CNC Machining Service

- Five-axis CNC Machine Tool

- Custom CNC Machining

- CNC Titanium Parts

- High-precision CNC Machining

- Tobacco Packaging Machine Components

- CNC Turning-Milling Compound Machining

- CNC Precision Grinding

Production Capacity:

10002

Delivery Timeframe:

Within 30 Days

Incoterms:

Not informedPackaging Details:

Not informed

More about

Hansheng Automation (Dongguan) Co., Ltd.

10-50

Employees

1

Sales volume (USD)

90%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Cam Indexers

- Hollow Rotary Tables

- Planetary Gearboxes

- Harmonic Drives

- Gear Manufacturer

- Custom Gears

- ISO 5 Gear Manufacturing

- High-Precision CNC Machining

- Custom CNC Machining

- Precision Castings Ver Mais

Contact and location

-

Karim ********

-

+86 1********

-

东莞市 / 广东省 | China